Electronic wire processing industry: the journey of precision manufacturing driven by technology

Jan 22, 2025

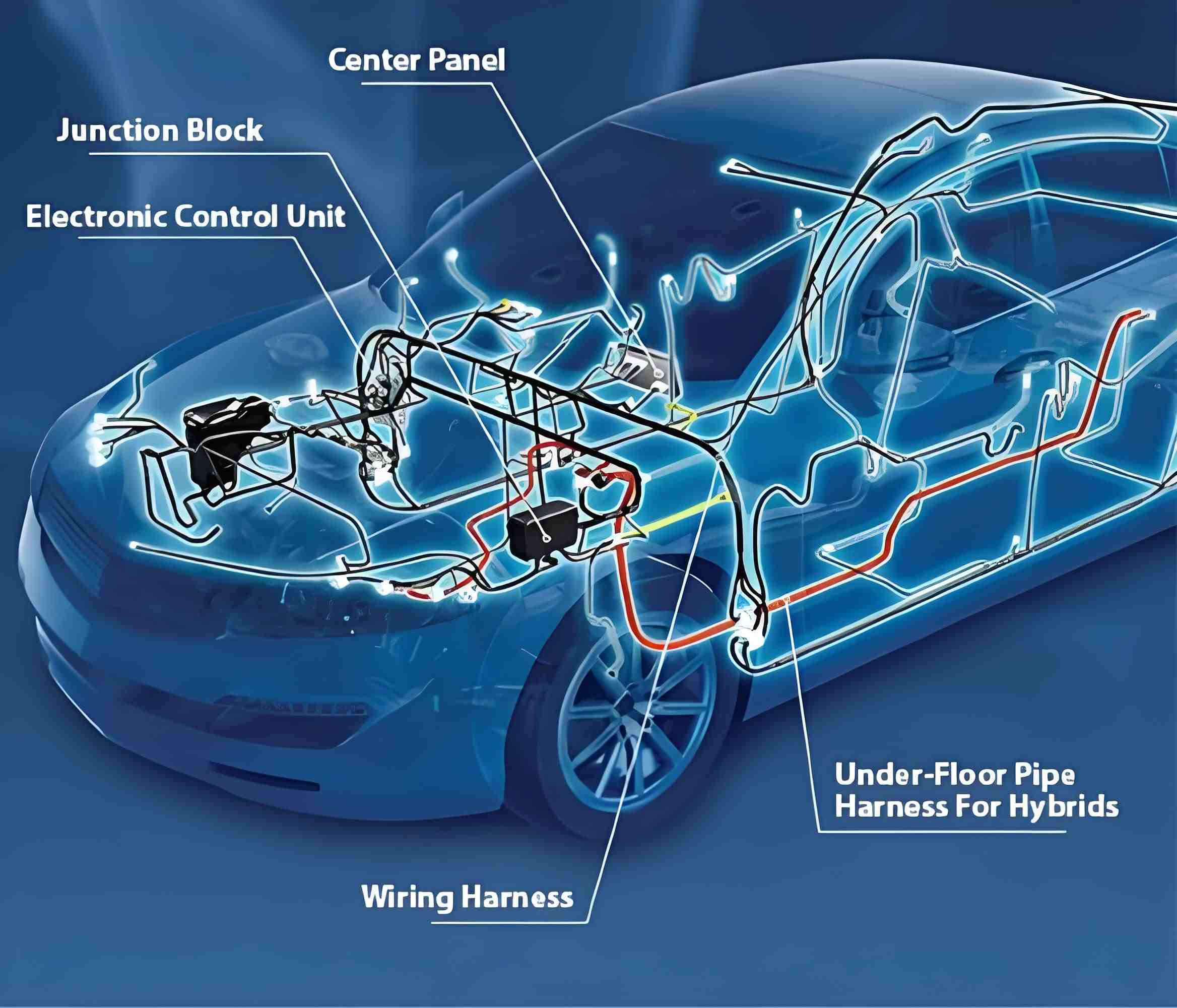

In today's era when the wave of digitalization is sweeping the world, electronic devices are everywhere, from the smartphones in our hands, the computers on our desks, to the complex electronic control systems in cars, all of which are inseparable from electronic wires. As a vital link in the electronic industry chain, the electronic wire processing industry is silently promoting the rapid development of modern science and technology with its unique charm and constantly innovative technology.

Analysis of the current situation of the electronic wire processing industry

The electronic wire processing industry is currently showing a situation of booming development and fierce competition. With the continuous expansion of the global electronics industry, the market demand for electronic wires is increasing day by day, not only in terms of quantity, but also in terms of quality, performance and variety. Strict requirements are put forward. From the traditional home appliance field to the emerging 5G communications, new energy vehicles, artificial intelligence and other cutting-edge industries, different application scenarios have spawned a variety of electronic wire needs. For example, the construction of 5G base stations requires RF coaxial cables with high frequency and low loss characteristics to ensure high-speed and stable transmission of signals; the battery connection system of new energy vehicles relies on special electronic wires with high temperature resistance and high current carrying capacity.

At the same time, there are many companies in the industry, and the degree of competition is intensifying. Large enterprises dominate the high-end market with their scale advantages, advanced technology and perfect supply chain system; while many small and medium-sized enterprises are struggling in the mid- and low-end markets, seeking survival and development space through differentiated competition, cost control and flexible market response capabilities. This competitive landscape has prompted the entire industry to continuously optimize and upgrade, accelerate technological innovation and product iteration.

Technological innovation promotes industrial upgrading

1. Material innovation: The innovation of electronic wire materials is the key to improving product performance. In recent years, new conductor materials such as high-purity oxygen-free copper, copper alloys and silver alloys have emerged continuously. These materials have excellent performance in conductivity, oxidation resistance and mechanical strength. At the same time, insulating materials have also made major breakthroughs, from traditional polyvinyl chloride (PVC) and polyethylene (PE) to high-performance insulating materials such as fluoroplastics and polyimides that are widely used today. Fluoroplastics have excellent high and low temperature resistance, chemical corrosion resistance and low dielectric constant characteristics, which can effectively reduce signal transmission loss and are suitable for high-end fields such as aerospace and military industry; polyimide has become an ideal choice for high-speed electronic wires and microelectronic equipment connecting wires with its excellent high temperature resistance and mechanical properties.

2. Manufacturing process optimization: Advanced manufacturing technology is the guarantee for high-precision and high-performance manufacturing of electronic wires. In terms of wire drawing technology, continuous drawing, multi-pass drawing and precision mold control technology can produce wires with finer diameters and higher precision to meet the development needs of miniaturization and lightweight electronic equipment. For example, when producing ultra-fine enameled wires, the wire diameter can be controlled below 0.01mm through precision wire drawing and painting processes, and the paint layer is uniform and firmly attached. In addition, the introduction of automated production equipment and intelligent manufacturing systems has greatly improved production efficiency and product quality stability. Automated cable arrangement and stranding equipment can accurately control the twisting pitch and arrangement of cables to ensure that the electrical and mechanical properties of cables are consistent; the intelligent manufacturing system can achieve accurate monitoring and optimization of the production process through real-time data collection and analysis, effectively reducing the scrap rate.

3. Upgrade of detection technology: To ensure that the quality of electronic wires meets strict standards, detection technology is also constantly upgrading. In addition to traditional electrical performance tests such as resistance, insulation resistance, and withstand voltage, advanced testing methods such as high-precision spectral analysis, scanning electron microscopy (SEM), and X-ray diffraction (XRD) are now widely used. Spectral analysis can accurately detect the impurity content in electronic wire materials to ensure material purity; SEM and XRD are used to observe the microstructure and crystal orientation of materials and evaluate the rationality of material properties and manufacturing processes. At the same time, the popularization of online detection technology and automated testing equipment has achieved real-time monitoring of each electronic wire in the production process, timely detection and elimination of unqualified products, and effectively guaranteed the reliability of product quality.

Challenges and coping strategies faced by the electronic wire processing industry

1. Fluctuations in raw material prices: The prices of metals such as copper and aluminum, the main raw materials for electronic wire production, are affected by factors such as international market supply and demand and geopolitics, and fluctuate frequently and with large amplitudes. The rise in raw material prices directly increases the production costs of enterprises and compresses profit margins. To meet this challenge, enterprises, on the one hand, strengthen strategic cooperation with suppliers, reduce the risk of price fluctuations by signing long-term supply contracts and establishing a stable supply chain system; on the other hand, actively carry out research on material substitution, explore the use of new composite materials or optimize product design, and reduce dependence on high-priced raw materials while ensuring product performance.

2. Increasingly stringent environmental protection requirements: With the increase in global environmental awareness, the electronic wire processing industry faces increasingly stringent environmental protection regulations. Some materials and processes used in the production process of traditional electronic wires may pollute the environment, such as PVC insulation materials that release toxic gases when burned, and some electroplating processes that produce wastewater containing heavy metals. In order to meet environmental protection requirements, enterprises have increased their investment in environmental protection technology research and development and equipment transformation. Use environmentally friendly insulation materials, such as degradable bio-based polymers, halogen-free flame retardant materials, etc.; optimize production processes, promote clean production technologies, and achieve the reduction and harmless treatment of wastewater, waste gas and waste residues; at the same time, strengthen the recycling of waste electronic wires, establish a complete circular economy system, reduce corporate environmental risks, and achieve sustainable development.

3. Intensified market competition pressure: As mentioned above, the electronic wire processing industry is highly competitive, and enterprises are facing dual competitive pressure from domestic and foreign peers. In order to stand out in the competition, enterprises must continue to strengthen technological innovation, improve product added value, and advance into the high-end market. Increase R&D investment, cultivate and introduce high-quality technical talents, establish an industry-university-research cooperation mechanism, and accelerate the transformation of scientific and technological achievements; strengthen brand building, establish a good brand image and enhance market competitiveness by improving product quality and service level; in addition, actively expand domestic and foreign markets, strengthen in-depth cooperation with downstream customers, provide customized product solutions according to customer needs, and improve customer loyalty.

Outlook on future development trends of the industry

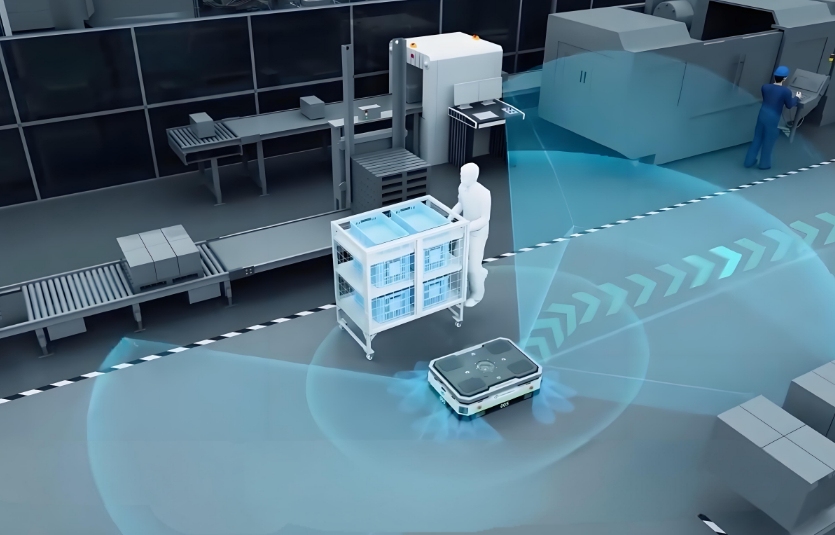

1. Intelligent manufacturing leads industry change: With the deep integration and application of emerging technologies such as artificial intelligence, big data, and the Internet of Things in the manufacturing industry, the electronic wire processing industry will usher in a new era of intelligent manufacturing. In the future, production equipment will have a higher level of intelligence, be able to achieve autonomous perception, decision-making and execution, and optimize production processes, improve production efficiency and reduce production costs through real-time analysis and processing of large amounts of data in the production process. At the same time, the intelligent manufacturing system will realize the information interconnection between various departments within the enterprise and between the enterprise and suppliers and customers, and build an efficient and collaborative industrial ecosystem.

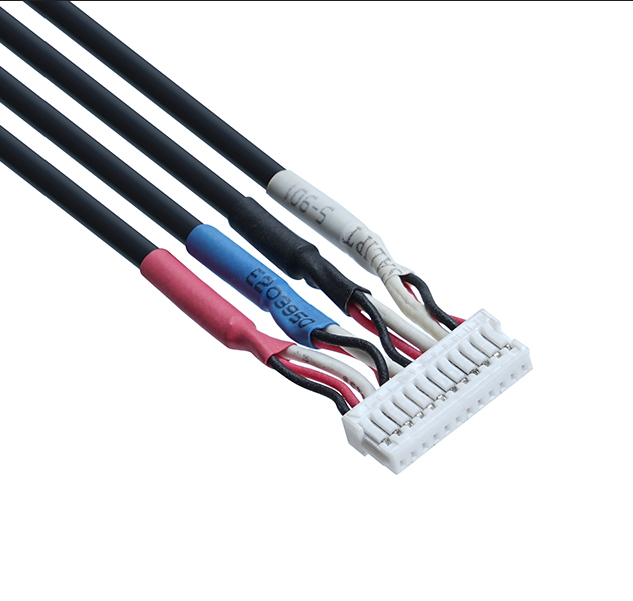

2. The demand for high-end and customized products is growing: As the electronics industry develops towards high-end and intelligent directions, the performance and quality requirements for electronic wires will continue to increase. High-end electronic wire products will show more outstanding performance in high-speed transmission, high-frequency signal processing, high temperature and high pressure resistance, and resistance to harsh environments. At the same time, in order to meet the personalized needs of different customers, the market share of customized electronic wire products will gradually expand. Enterprises need to have stronger R&D capabilities and rapid response capabilities, and develop customized product solutions based on customer-specific application scenarios and technical requirements to adapt to the diversified changes in market demand.

3. Green and environmental protection has become the mainstream of industry development: Driven by the global concept of sustainable development, green and environmental protection will become the main theme of the future development of the electronic wire processing industry. From raw material selection, production process optimization to product recycling, the entire industry chain will transform and upgrade in the direction of green and environmental protection. The research and development and application of environmentally friendly materials will be more extensive and in-depth, clean production technology will be fully promoted, and the recycling rate of waste electronic wires will continue to increase. Only by actively practicing the concept of green development can enterprises take the initiative in future market competition and achieve a win-win situation of economic and environmental benefits.

As a basic supporting industry of the electronic information industry, the electronic wire processing industry is constantly radiating new vitality and vigor driven by technological innovation. Despite facing many challenges, as long as enterprises in the industry can seize opportunities, actively respond, and continue to increase investment in technology research and development, product innovation, green environmental protection, etc., they will surely be able to achieve greater development achievements in future market competition and make greater contributions to promoting the prosperity and development of the global electronics industry.

Network Supported

Network Supported