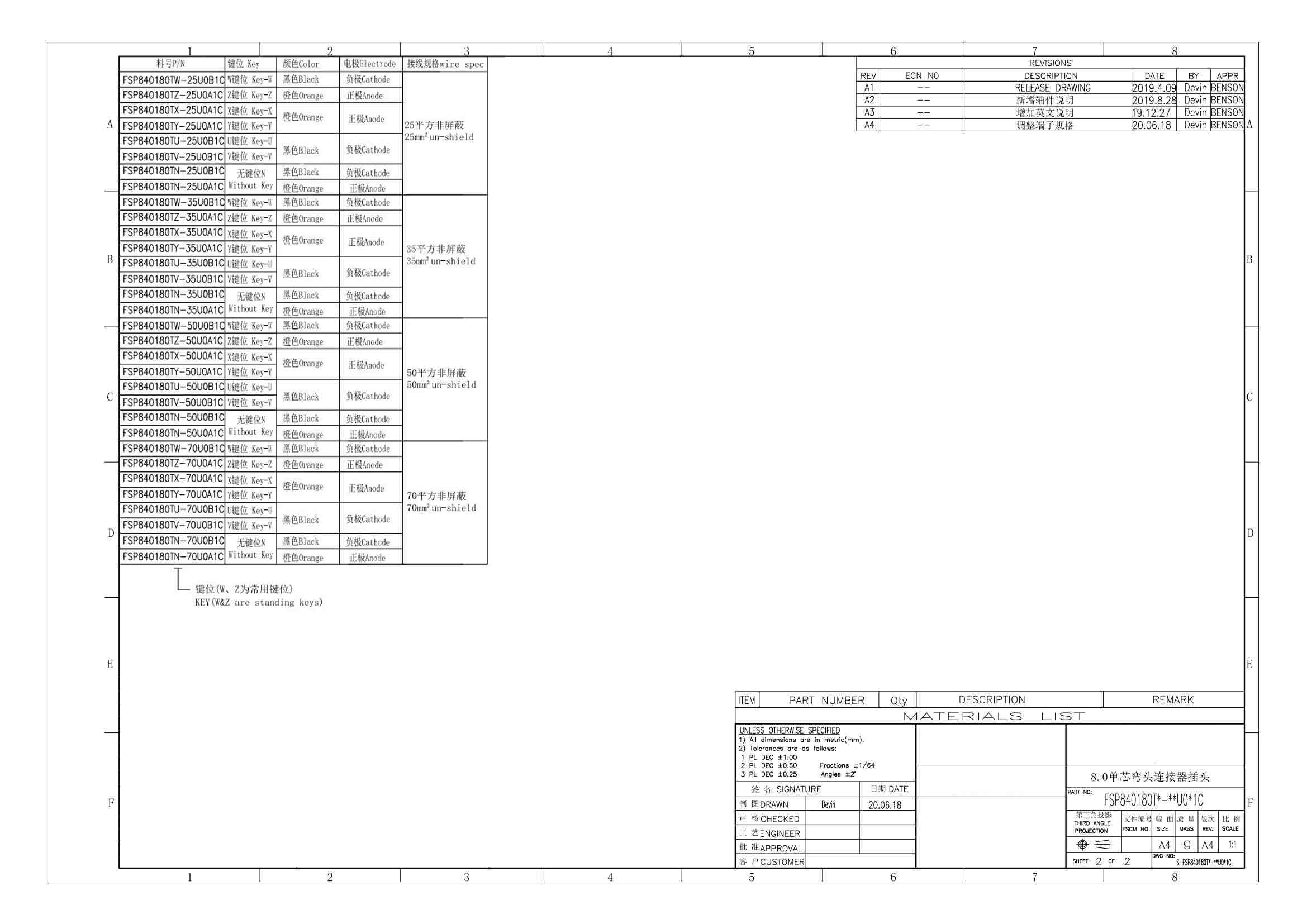

This power harness for battery cabinets is made of environmentally friendly materials compliant with ROHS and UL standards. It supports customization of wire gauges (standard 35mm² with customizable options) and connectors (standard FSP840180TZ - 35U0A1C with customizable options). Dimensions are set according to customer requirements, and the minimum order quantity is negotiable. It is suitable for automotive battery power systems and uses a hexagonal riveting process to ensure stable power transmission.

This power harness is specially developed for battery cabinet applications, offering reliable electrical performance and durable construction. It is widely used in energy storage systems, backup power supplies, industrial cabinets, and other high-current environments. With flexible customization on size, connectors, and packaging, it can meet various installation and system requirements.

Product Overview

Material and Quality

Packaging and Delivery

Typical Applications

This power harness is primarily used in battery cabinet systems that require stable and high-current electrical connections. It is well-suited for integration into various industrial and commercial environments, including:

Commonly installed in lithium battery packs and cabinet-based storage units, the harness ensures efficient power transmission between cells, modules, and controllers. It helps maintain system stability and supports rapid charge-discharge cycles.

In server rooms, data centers, and telecom base stations, this cable serves as a key internal connection for backup battery modules, offering reliable operation in case of grid failure or voltage fluctuation.

Used within equipment cabinets at base stations and signal relay points, the cable supports continuous power delivery and minimizes the risk of connection failures in remote or harsh environments.

Suitable for DC-side wiring in solar inverter cabinets and battery units, providing safe and durable performance in residential, commercial, or off-grid installations.

Applied in automation control cabinets and heavy machinery systems where large currents and secure terminals are required. It is often used to connect battery packs, control modules, and distribution terminals.

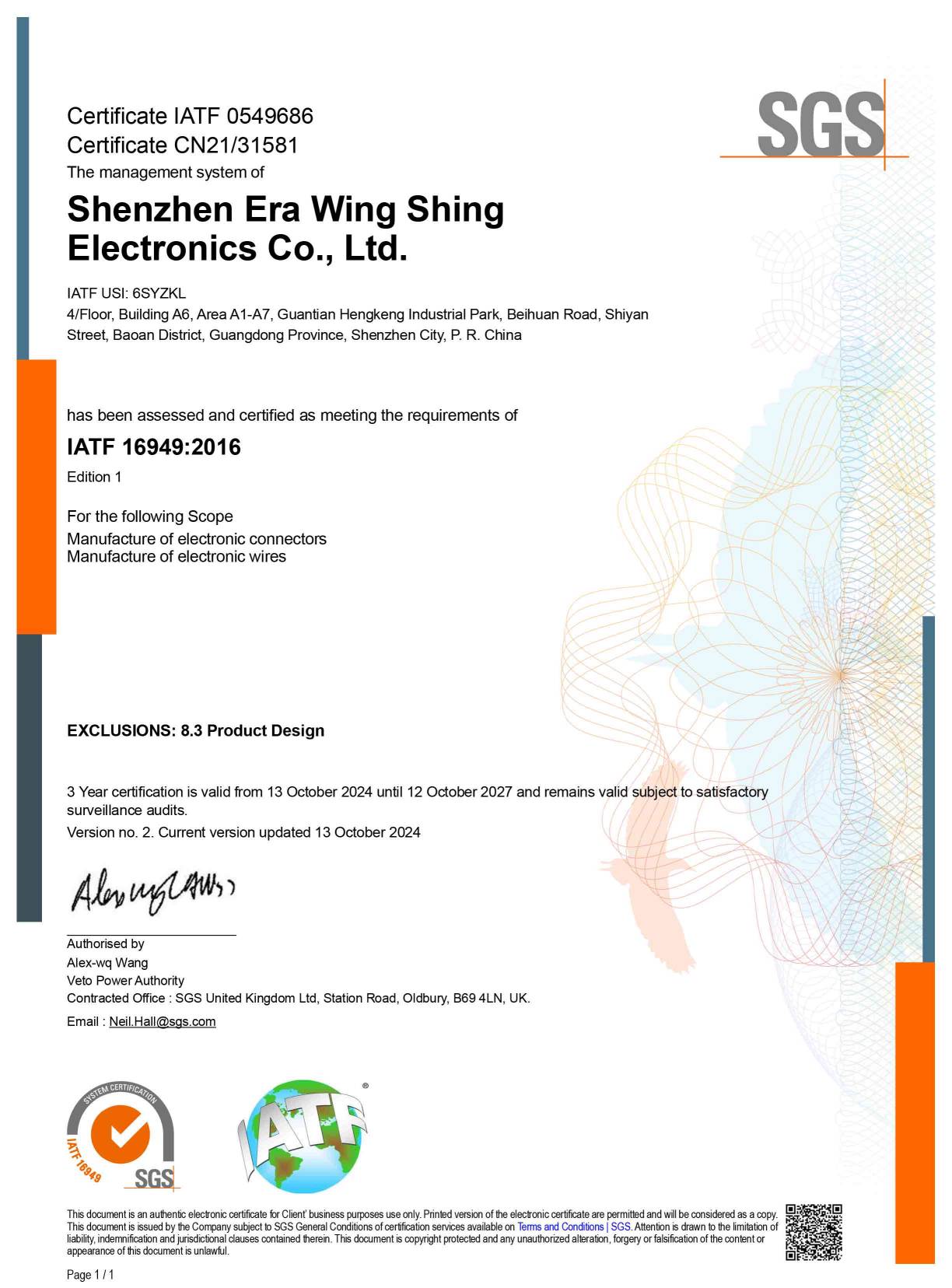

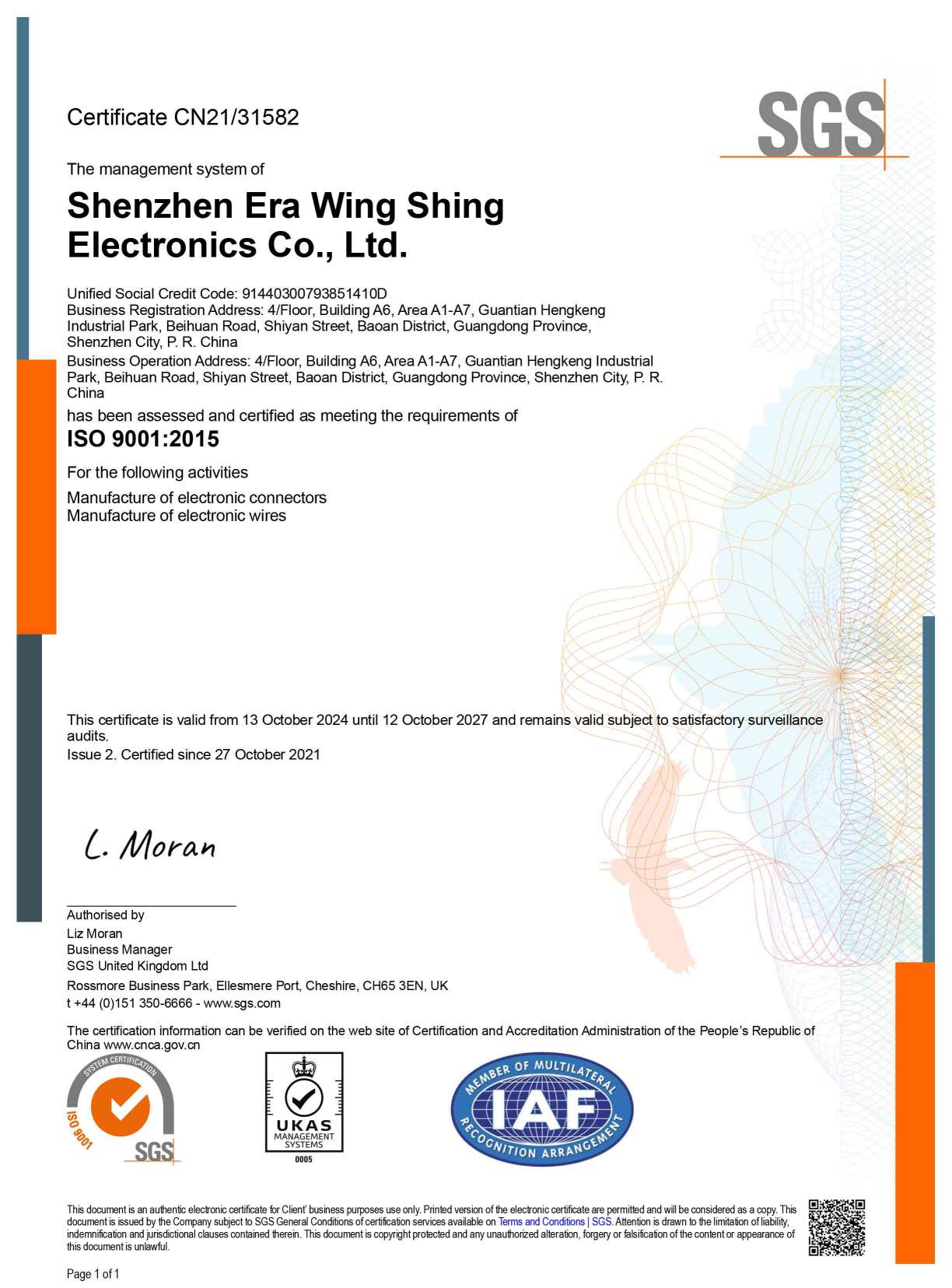

Certification

Why choose us?

Over 25 Years of Manufacturing Experience

Over 25 Years of Manufacturing Experience

Certified Quality Management Systems

Certified Quality Management Systems

Strong Track Record of Continuous Improvement

Strong Track Record of Continuous Improvement

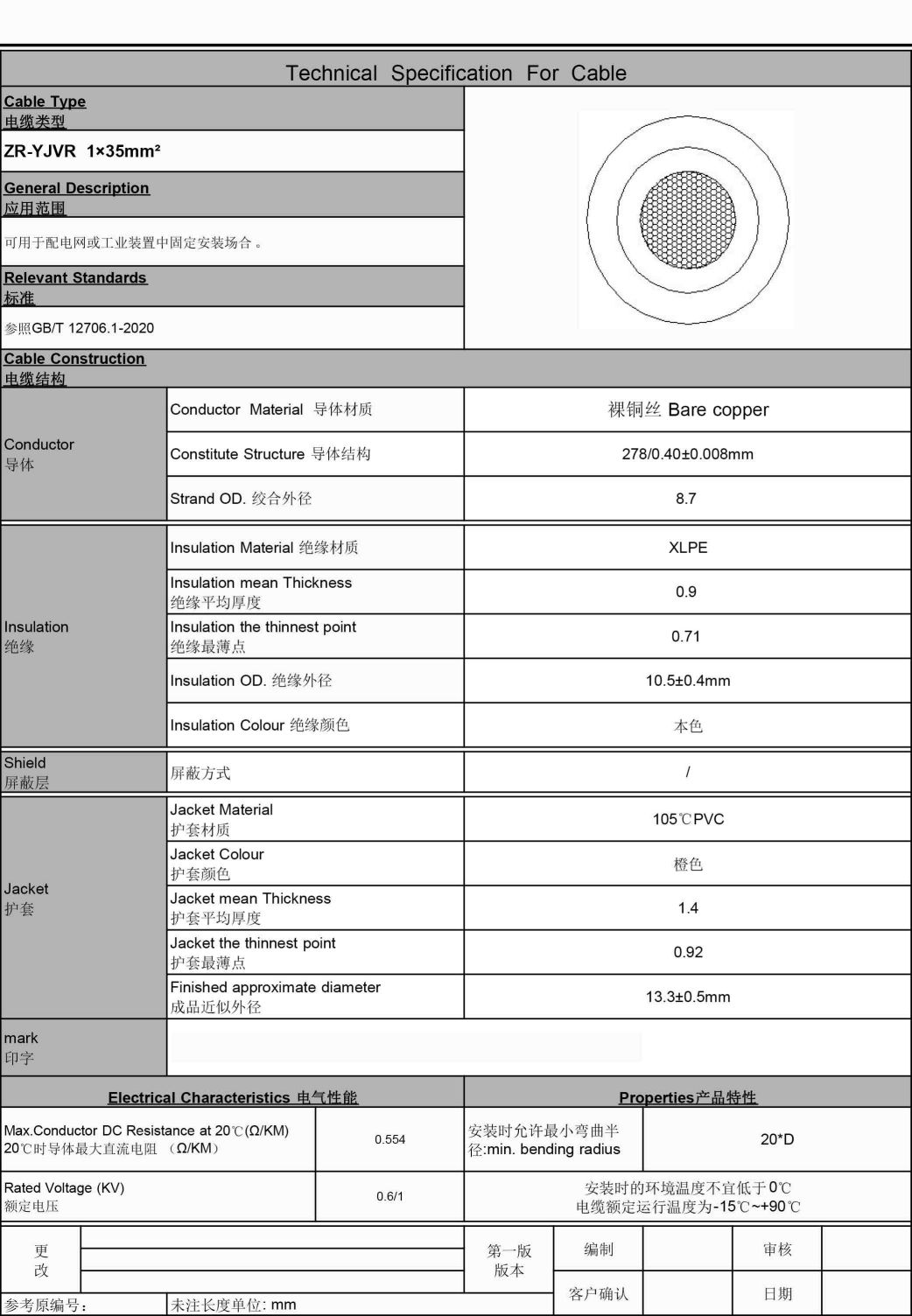

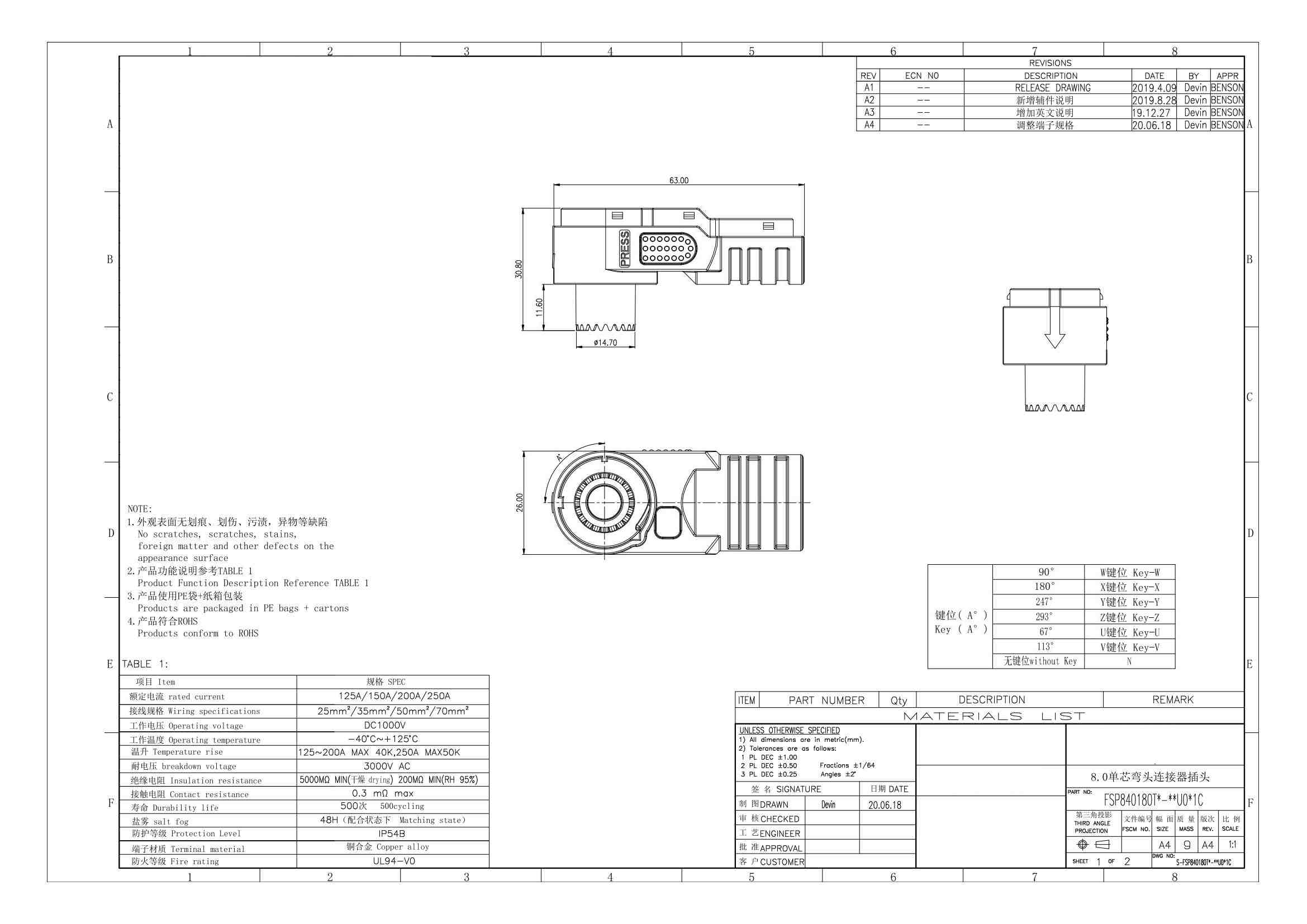

5. Specifications

FAQ

Q1: Can I customize the wire gauge, connector type, or cable length?

A1: Yes, we offer full customization options based on your specific application. Wire gauge, connector model, cable length, and even color can be tailored according to your requirements.

Q2: What certifications do your products and factory have?

A2: Our factory is certified with ISO 9001:2015 and IATF 16949 for automotive quality management. In addition, our products are UL certified and all materials comply with ROHS and UL standards.

Q3: What industries do you mainly serve?

A3: We provide power harness solutions for energy storage systems, telecom cabinets, UPS backup systems, solar power setups, and industrial automation panels.

Q4: Do you have experience in OEM/ODM projects?

A4: Yes. With over 25 years of manufacturing experience, we specialize in both OEM and ODM projects. We can support design, prototyping, and volume production based on your drawings or specifications.

Q5: What is your typical lead time?

A5: Lead time varies based on order size and customization level. Generally, we confirm delivery time during order negotiation to ensure it meets your project schedule.

Q6: How are the cables packaged and shipped?

A6: Standard packaging includes bundling with cable ties and bubble wrap protection. Custom packaging and labeling are also available. We offer flexible shipping methods such as express delivery, sea freight, and air freight.

Q7: What is the minimum order quantity (MOQ)?

A7: Our MOQ is flexible and can be negotiated based on the product specification and order volume.

Please Read On, Stay Posted, Subscribe, And We Welcome You To Tell Us What You Think.

Copyright @ 2026 ShenZhen Era WingShing Electronics Co.,Ltd. All Rights Reserved.  Network Supported

Network Supported